Setup wiring with the battery lying in the compartment. Still not anything permanent, but this lets me shorten all the wires and reduces the chances of knocking something loose while kicking.

Friday, February 28, 2014

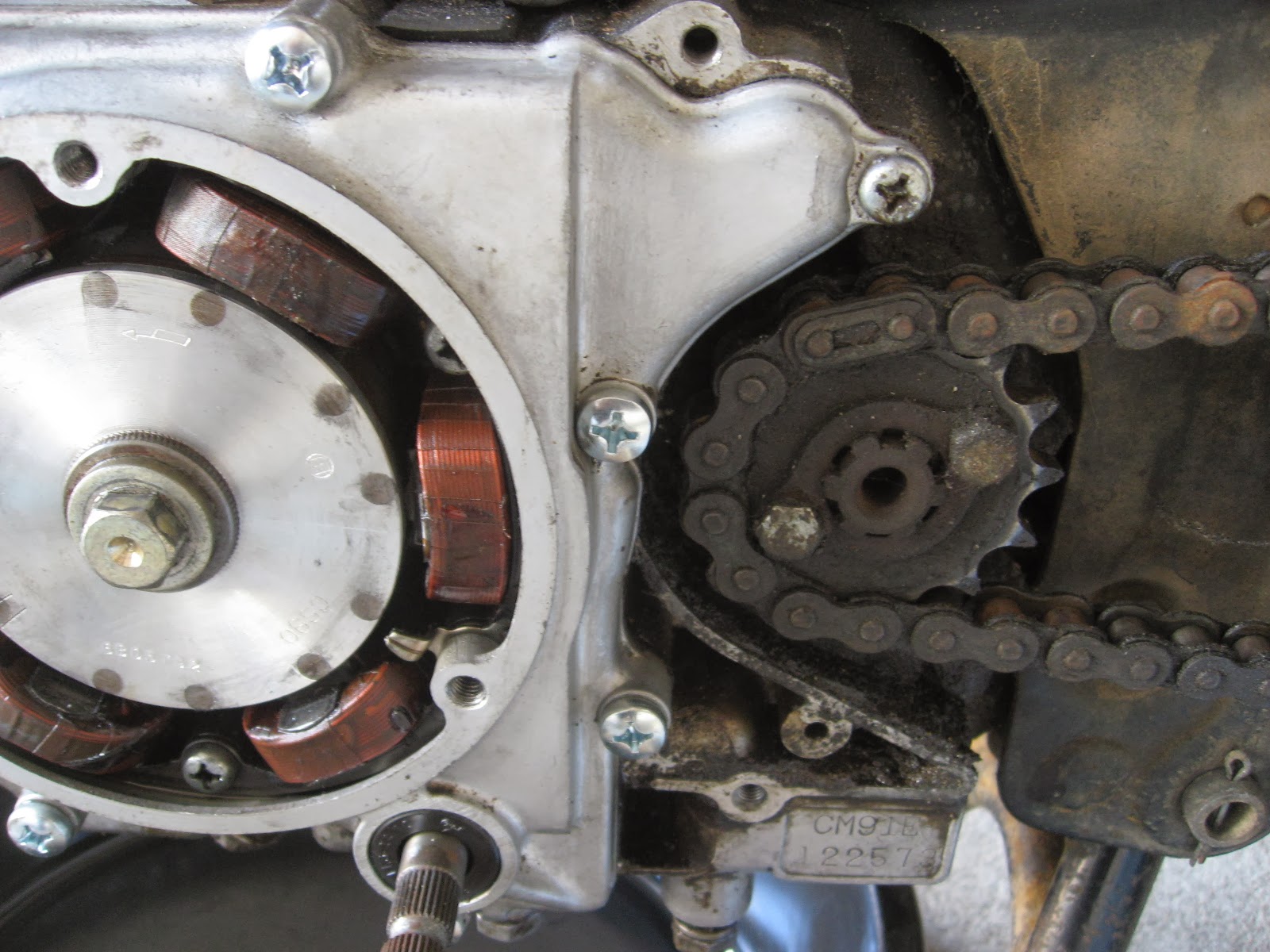

Roxy: Not Elegant

Not a very elegant setup, but it'll do temporarily to stop the oil spray while I"m trying to do dynamic timing.

Labels:

1964 S90,

alternator,

timing

Thursday, February 27, 2014

Roxy: Timing, Timing, Timing

Took the new Actron CP7529 Digital Timing Light out for its first spin today. Also had to shell out for an auxiliary 12v battery. The positive and negative leads on the light go to the battery, the pickup goes to the spark plug wire, and then you connect the battery negative to an engine ground. Worked like magic.

But... no one mentioned the oil spray. Actually, once I had the alternator cover off, I did think to myself, "How will this spin without making a giant mess in the process?" And sure enough, with the engine running and alternator spinning, a fine mist of oil sprayed out as expected.

Turns out you need to make either a cover with a small open window, or even a solid plexiglass one, so you can see the timing marks without getting sprayed. Good to know...

But before I had the cover off, I did use the light just in RPM mode to finally set a good idle. It was definitely idling way too fast, which I already knew. Used the idle screw to bring it down to hover around 1350 or so. At that speed, the timing mark looked to be between the F and T. So slightly retarded.

New carb settings: air screw at 1 turn even, idle screw only 1/4 turn out.

But then I did a static timing test. I thought I'd done it before, back when I was having all the carb issues, but checking my notes, I don't think I ever did.

The shocker here was that when I checked with just the static light, the points were opening after TDC. I've got a thread going on the S90 forum about whether this could be related to the engine work. No definite answers yet. Next step is I need to rig that oil shield and check advance timing.

But... no one mentioned the oil spray. Actually, once I had the alternator cover off, I did think to myself, "How will this spin without making a giant mess in the process?" And sure enough, with the engine running and alternator spinning, a fine mist of oil sprayed out as expected.

Turns out you need to make either a cover with a small open window, or even a solid plexiglass one, so you can see the timing marks without getting sprayed. Good to know...

But before I had the cover off, I did use the light just in RPM mode to finally set a good idle. It was definitely idling way too fast, which I already knew. Used the idle screw to bring it down to hover around 1350 or so. At that speed, the timing mark looked to be between the F and T. So slightly retarded.

New carb settings: air screw at 1 turn even, idle screw only 1/4 turn out.

But then I did a static timing test. I thought I'd done it before, back when I was having all the carb issues, but checking my notes, I don't think I ever did.

The shocker here was that when I checked with just the static light, the points were opening after TDC. I've got a thread going on the S90 forum about whether this could be related to the engine work. No definite answers yet. Next step is I need to rig that oil shield and check advance timing.

Wednesday, February 26, 2014

Astrid: Tank Cleaning

Removed the tank, which turned out to be as easy as removing four bolts. Pulled the fuel lines out so I could shake the big rust chips out of the tank. Then I re-attached the tank, but let the fuel lines poke out of the battery compartment. It should be pretty easy to run new lines when I'm ready.

Plugged the fuel lines with golf tees and filled the tank about half full of Evapo-Rust.

Plugged the fuel lines with golf tees and filled the tank about half full of Evapo-Rust.

Labels:

CM91,

fuel system,

restoration,

Run Astrid Run

Monday, February 24, 2014

Garage: Another Head

Got a head off eBay for $23 shipped. Looked to be in pretty rough shape out of the box, but I haven't done anything to clean it yet. Also, looks like there's a completely stripped screw on the rocker cover (I really should have checked for any stuck screws before I bought it).

But if nothing else I can use it to practice valve lapping using the new Lisle valve lapper I also got today.

But if nothing else I can use it to practice valve lapping using the new Lisle valve lapper I also got today.

Labels:

top end,

used parts

Astrid: Gas Tank Testing

At the risk of adding even more corrosion to the inside of the tank, I ran water through Astrid's reserve line to see if a lot of gunk would come out. There was some sediment, but nothing a good filter couldn't handle. The bigger chunks stayed inside the tank as expected.

I'm considering filling the tank with Evapo-Rust and letting it sit for a couple days before then flushing it out again and finally replacing with gas.

Though with all the sparking going on, I'm still a bit nervous having gas in the metal tank. Maybe I should leave the Evapo-Rust in until a more permanent (non-sparking) battery solution is in place. Wouldn't hurt to let the Evapo-Rust sit for as long as possible anyway.

The old fuel filter cracked and the rubber fuel lines themselves are brittle and perished. I'll need to see about replacing the fuel lines completely.

I'm considering filling the tank with Evapo-Rust and letting it sit for a couple days before then flushing it out again and finally replacing with gas.

Though with all the sparking going on, I'm still a bit nervous having gas in the metal tank. Maybe I should leave the Evapo-Rust in until a more permanent (non-sparking) battery solution is in place. Wouldn't hurt to let the Evapo-Rust sit for as long as possible anyway.

The old fuel filter cracked and the rubber fuel lines themselves are brittle and perished. I'll need to see about replacing the fuel lines completely.

Labels:

CM91,

fuel system,

Run Astrid Run

Roxy: Original Airbox

Took some time to open up and WD40 the airbox that came as spare parts for Roxy. It's in excellent condition. The only thing I'd replace is the plastic side cover on one side (the other side is chrome).

Even the air filter element was in good condition.

Even the air filter element was in good condition.

Sunday, February 23, 2014

Astrid: On a Roll...

So the oil leak turned out to be just a few alternator cover screws that weren't tightened down. They were the 3 that were hidden by the sprocket cover. Replaced them and tightened them and wouldn't you know it - no more leak.

Tested the homemade static timing light for the first time. Worked like a charm.

I must have confused the S90 and CM91 kickstarters at some time in the past, since this one that was on Viola has way more clearance.

Original battery is a 6N5.5 - 1D by Cycle Tron.

Tested the homemade static timing light for the first time. Worked like a charm.

I must have confused the S90 and CM91 kickstarters at some time in the past, since this one that was on Viola has way more clearance.

Original battery is a 6N5.5 - 1D by Cycle Tron.

Labels:

battery,

CM91,

electrical,

restoration,

Run Astrid Run,

timing,

top end

Friday, February 21, 2014

Astrid: A Rookie Wrench Milestone

After three years of sitting, and countless disassembly and reassembly by this rookie, Astrid's engine fires up and idles! It's definitely a milestone. Probably less to do with my mechanical skill, and just the bullet proof nature of these old Honda engines.

Had a little confusion at first rigging up the killswitch, as I had the wires running to the wrong leads. After sorting that out, I rigged up the aux gas bottle, ending up just hanging it off a handlebar. I poured in a little bit of gas and opened up all the petcocks, then checked the carb for leaks.

At that point I moved the bike out into the open where if she caught fire at least we wouldn't burn the garage down.

The first few kicks did nothing. After a half dozen of these, the kickstarter came loose and I had to re-attach it. I kept kicking, knowing from the compression test that it took awhile to get up to 120lbs and maybe the oil still needed to be distributed evenly. Eventually I thought I heard a little mutter right at the bottom of each stroke. When she caught, she just fired right up without any hesitation. There was smoke from the exhaust for a minute or two, and I was revving the throttle to keep her running.

Eventually I just let her idle and she ran strong for a few minutes. She then sputtered and stalled, which may have been because I left the choke open. But at that point, I'd already seen the massive oil leak coming from the right bottom corner of the alternator cover. So I didn't start her up again, figuring the day was still an unqualified success.

Had a little confusion at first rigging up the killswitch, as I had the wires running to the wrong leads. After sorting that out, I rigged up the aux gas bottle, ending up just hanging it off a handlebar. I poured in a little bit of gas and opened up all the petcocks, then checked the carb for leaks.

At that point I moved the bike out into the open where if she caught fire at least we wouldn't burn the garage down.

The first few kicks did nothing. After a half dozen of these, the kickstarter came loose and I had to re-attach it. I kept kicking, knowing from the compression test that it took awhile to get up to 120lbs and maybe the oil still needed to be distributed evenly. Eventually I thought I heard a little mutter right at the bottom of each stroke. When she caught, she just fired right up without any hesitation. There was smoke from the exhaust for a minute or two, and I was revving the throttle to keep her running.

Eventually I just let her idle and she ran strong for a few minutes. She then sputtered and stalled, which may have been because I left the choke open. But at that point, I'd already seen the massive oil leak coming from the right bottom corner of the alternator cover. So I didn't start her up again, figuring the day was still an unqualified success.

Labels:

CM91,

restoration,

Run Astrid Run

Wednesday, February 19, 2014

Astrid: The Final Stretch

Some odd jobs, but this pretty much gets us to the final point. The only thing left to do is rig up the killswitch and secure the wiring, and also decide how to hang the gas bottle. From there, it's just kick and cross your fingers.

Carb gets mounted and air hose attached (which was a pain to fit).

700 mL of the Castrol 20W50.

Something odd - if you attach the kickstart lever flush to the case, it won't clear the exhaust on the way down. I'm not sure what's out of whack. Maybe it's the wrong model of kickstarter, or maybe it's the wrong exhaust. But either way, I had to mount the lever out at the very edge in order to get a full rotation. I think for the short term it will have to do.

And the big moment - 120 lbs on the compression test!

Carb gets mounted and air hose attached (which was a pain to fit).

700 mL of the Castrol 20W50.

Something odd - if you attach the kickstart lever flush to the case, it won't clear the exhaust on the way down. I'm not sure what's out of whack. Maybe it's the wrong model of kickstarter, or maybe it's the wrong exhaust. But either way, I had to mount the lever out at the very edge in order to get a full rotation. I think for the short term it will have to do.

And the big moment - 120 lbs on the compression test!

Labels:

carburetor,

CM91,

compression,

oil change,

restoration,

Run Astrid Run

Sunday, February 16, 2014

Astrid: Marathon

Solid four hours of quality garage time today. Did a laundry list for Astrid run prep, pretty much everything leading up to adding oil and then doing the compression test.

These 2 gaskets were original, I'd just fallen into the habit of leaving them off.

These 4 gaskets came from the replacement kit. I'm not 100% sure the o-ring for the oil galley is correct, but it seemed to fit and it was better than nothing.

The locking tab (before bending the tabs), the C-clamp setup, and a clean oil filter screen.

- Added in all the gaskets, using 4 from the replacement kit.

- Torqued the clutch nut, which actually turned into a bit of an ordeal, but learned 2 good tricks as a result.

- First, realized that I had the perfect sized C-clamp to keep the clutch basket holder from moving as you apply force to the nut.

- Second, on a brand new lock ring, you need to bend the tabs inward otherwise it's tough to fit a screwdriver behind the tab once it's tightened.

- Did a mini tune-up

- Set the valve clearance, using the yellow 3mm wrench for the first time

- Set the points gap. Weird thing about the points gap is that since the whole thing rides on a spring, it seems tricky to use a feeler gauge to measure the space in between.

- Checked the timing, and realized after much confusion, that my homemade LED was not working because LED's don't dim. Switched back to the incandescent bulb setup and found the timing was already dead on to the "F" mark.

These 2 gaskets were original, I'd just fallen into the habit of leaving them off.

These 4 gaskets came from the replacement kit. I'm not 100% sure the o-ring for the oil galley is correct, but it seemed to fit and it was better than nothing.

The locking tab (before bending the tabs), the C-clamp setup, and a clean oil filter screen.

Labels:

clutch,

CM91,

gasket inventory,

restoration,

Run Astrid Run,

top end,

top tip,

tune up

Saturday, February 15, 2014

Astrid: Bling

Replaced all the fasteners on the alternator and clutch covers. The hardware store was fresh out of 6x20 plain steel screws so I ended up getting stainless at $.90 a pop, but I didn't feel like waiting to check other stores.

Also, tried tightening up the exhaust bolts to see why there was such a big gap there. I'm fairly certain it's not supposed to be that way, but I'm not sure if it really matters. Going to try swapping it with Viola's to see if I can at least cut the gap down.

Also, tried tightening up the exhaust bolts to see why there was such a big gap there. I'm fairly certain it's not supposed to be that way, but I'm not sure if it really matters. Going to try swapping it with Viola's to see if I can at least cut the gap down.

Labels:

CM91,

exhaust,

restoration,

Run Astrid Run

Subscribe to:

Comments (Atom)